Page 1 of 2

Align hull properly before tack welds

Posted:

Wed Apr 23, 2014 11:10 amby craig

Hi all,

I am slowly forcing my hull panels together. The shear amount of compressive force on these panels doesn't really sink in until you are doing it yourself. I think I am going to have a 3/16 gap along the lower/upper panel seam from the bow back about a foot and a half. Just can't get it to fully come together. I used the wooden blocks on both sides screwed together to force alignment of the panels, so at least they align properly athwartship even if they aren't fully pressed together top-to-bottom.

My question: how do I verify that the hull is aligned properly? I want to make ABSOLUTELY sure before I start gluing. I know to measure from bow to both sides of stern - should be the same diagonal in both cases. There is also some stuff on the CLC website for kayaks where you clamp the boat to a sawhorse and physically twist it to be square. But that obviously isn't possible here.

Any suggetions?

Re: Align hull properly before tack welds

Posted:

Wed Apr 23, 2014 12:56 pmby DanaDCole

All I can say is I have almost exactly the same width and length of gap you describe. It is almost equal on both sides as far as I can tell, so that gives me some small comfort. This is after using 2x4s and long bar clamps to pull the lower panels up as much as I dared.

If it will help, I can tell you that I put a 2x4 across the side panels just aft of bulkhead 1 and used two small clamps behind the bulkhead to keep the 2x4 from sliding forward. I put a second 2x4 under the bow, just forward of the steepest curve upward, with long bar clamps on each side. I slowly tightened the clamps, one side then the other, until the lower panels started to separate at the lower seam. That was the "far as I dared" point. If you were able to get the gap down by hand to as small as I did with clamps, then that might do the trick for you. Just don't put on too much pressure! I think if you can get the gap down pretty small, and it is even on both sides, you ought to be OK, but let's wait to see what others say.

I'm going to wait and hear what others say--have done some of the gluing but none up at the bow end yet. The thing about measuring from the bow to each side of the stern is it only tells you about the algnment at the top of the bow--which is not in the water. I don't know any way to measure the bottom of the bow, which is in the water where it matters most. One thing is that if the top of the bow is aligned and all the edges of the panels are touching (or have the exact same small gap on each side) then the bottom must also be in alignment (maybe).

If we don't get any brilliant insights from the posts that follow, the way I see it is the only choice I have is to go ahead with it. Any small misalgnment of the bow will be corrected with helm position. This does not help with speed, but I'm not planning on any racing. Upwind, speed lost on one tack should I think be partially made up on the opposite tack. I'm just hoping that if I have to glue it as is, those wide seams will hold.

Re: Align hull properly before tack welds

Posted:

Wed Apr 23, 2014 1:05 pmby craig

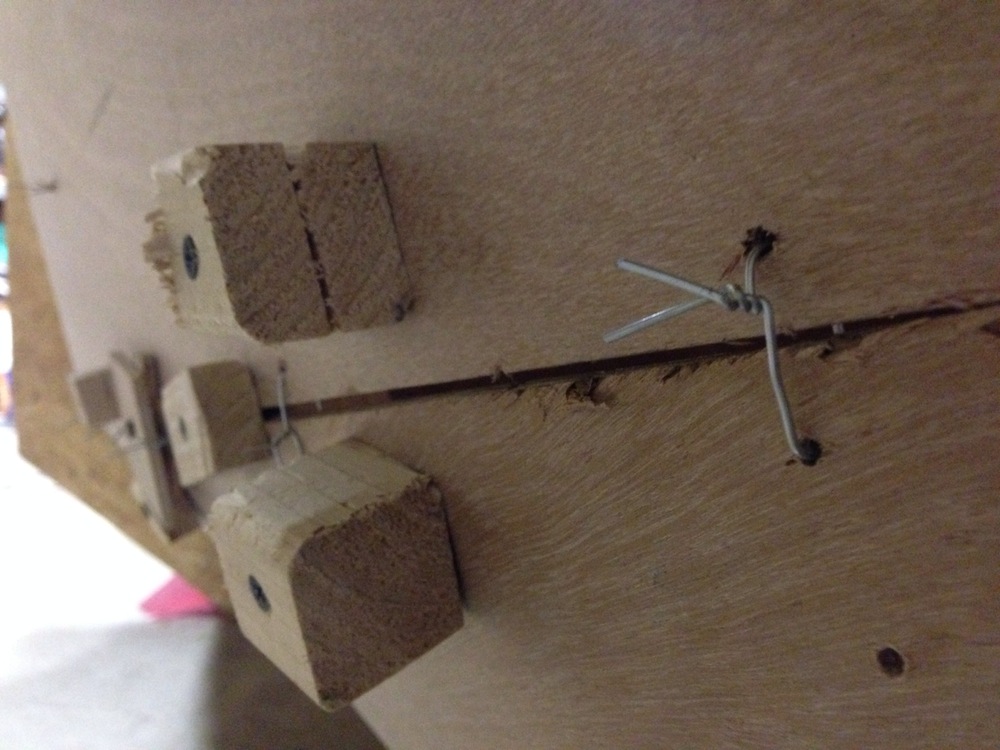

Here are two pictures of bow (port and starboard sides)

You can kinda see the gap: a little light is shining through. It's starting to look like swiss cheese up there with all the blocks and holes in the hull trying to pull everything into alignment. We're lucky the gap is identical between port and starboard!

Screwing a piece of wood with a backing plate right at the seam helped tremendously in bringing the two panels together. Before I was just clamping top-to-bottom, but that would force the top panel INSIDE the middle one. Adding the blocks right along the seam forced the two to stay in alignment. Really recommend that to other builders.

- 20140423_133530675_iOS.jpg (168.84 KiB) Viewed 10293 times

- 20140423_133525628_iOS.jpg (178.76 KiB) Viewed 10304 times

Re: Align hull properly before tack welds

Posted:

Wed Apr 23, 2014 1:30 pmby DanaDCole

Yes, that gap looks almost exactly the same as mine. I would not be surprised to learn that we are not the only ones.

Re: Align hull properly before tack welds

Posted:

Wed Apr 23, 2014 1:44 pmby truenorth

That's looking pretty good. That's how mine started, too, though I got mine a little closer eventually. Use 2 contraptions with their own clamps 3-4 inches apart to pull the gap together and then tighten the wires. Maybe you did, but I only see one? Use 3, or 4 if necessary.

You're going to spend quite a bit of time later filling and fairing so don't worry about how many holes you poke in the boat at this stage.

/tn

Re: Align hull properly before tack welds

Posted:

Wed Apr 23, 2014 1:56 pmby DanaDCole

Wish I had thought of that! Small blocks attached above and below gap so you can use c-clamps to pull the panels together. Might need one every 4 to 6 inches along the gap.

One possibility is that the 1/4" screws on the alignment blocks could be holding the panels apart. I used a rat-tail rasp to make spaces for the screws. You have to be careful to be sure the screws stay aligned with the rasped-out spaces while you tighten them.

Will try the block-and-clamp idea soon.

Re: Align hull properly before tack welds

Posted:

Wed Apr 23, 2014 5:13 pmby DanaDCole

Wow! That worked like a charm. Thanks truenorth and craig. If it wasn't for this forum I'm afraid my boat would be a complete disaster by now.

Anyway, I was able to pull the panels snug with a couple of sets of cleats and clamps on each side. The only problem now is that between the alignment blocks and clamping cleats I didn't have a heck of a lot of gluing area left (the cleats don't cover the seam but there is not enough room to get at it). What I'll do is wait for this glue to set up for a couple days, then remove the alignment blocks, leaving the clamps in place. Then I can glue the sections that were under the alignment blocks and that should hold.

Re: Align hull properly before tack welds

Posted:

Wed Apr 23, 2014 5:27 pmby herbt

Welcome to the club. This is a very difficult joint, I finally got mine to about 1/16 apart and called it a day. Keep using the alignment tool and the C clamp blocks and slowly coax it together as recommended by truenorth. I also doubled up on the wires to get a couple more twists before breaking. I would be wary about methods that could distort the hull or fracture a panel. When you get it as close as you can use large tacks. and it will hold. I also taped the joint on the inside using 4 inch tape filled well with epoxy .

Herb

Re: Align hull properly before tack welds

Posted:

Wed Apr 23, 2014 11:00 pmby truenorth

Here's my write up from when I had to deal with this. Nothing genius from me -- just passing on info from other builders! The key to a good alignment is to have one of the blocks longer than the other so it can 'spin'.

http://sunmonkeypocketship.blogspot.com ... -time.htmlIt's funny as I read that back... it was May when I wrote that and I thought I'd be done with the electronics and the cabin sole "in a month." The cabin sole didn't get done until February and the electronics until March.

Re: Align hull properly before tack welds

Posted:

Thu Apr 24, 2014 9:15 amby craig

Thanks Truenorth and Dana, got mine done last night. Wow, what a struggle. Good idea making a hole for the screw along the seam - I can imagine the screw was holding the panels apart a little bit. Glad that's done.

I still need to check for twist in the hull. I found this quote on the forum from Jon about the issue:

I originally did a ton of diagonal measuring to elimiate any twist, but for quick twist checks now, I'll run a level athwartships at Bulkhead #2 and at the transom, and then shim the cradle until both are level. I spot check for twist pretty often since I put my cradle on wheels, so I could occasionally reposition the boat if I needed to make extra room in the shop. I guess my shop floor isn't very even, because every time I move the boat, it throws the level/twist off a little.

If anybody has any other tips/suggestions for making sure there isn't any twist in the hull, I'd appreciate it too.